Flux-Cored Welding Basics

About Instructor

OVERVIEW

Flux-Cored Welding can be an excellent process to use for welders of all skill levels who frequently need to weld outside or on dirty material.

Works as well as Stick on dirty or rusty material

Out-of-position welding

Deep penetration for welding thick sections

Increased metal deposition rate

More forgiving when welding on dirty or rusty metal

The main difference between flux cored arc welding and MIG welding is the way the electrode is shielded from the air. Flux cored welding gets its shielding from the flux core, and this allows the operator to weld outdoors where it is windy. Another process, gas-shielded flux-cored welding, does require a shielding gas. It’s often used in heavy-duty industrial fabrication and manufacturing.

Flux-cored welding does produce a slag that sits on top of the finished weld and must be chipped off, similar to stick welding, and it also tends to produce welds that aren’t as visually attractive as MIG welds. For these reasons, if you own a power source capable of performing MIG and flux-cored welding, it makes sense to switch to the MIG process for welds that will be made indoors.

First things first

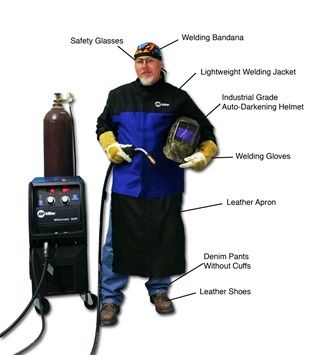

Before tackling any welding project, make sure you have the proper safety apparel and that any potential fire hazards are removed from the welding area. Basic welding safety apparel includes leather shoes or boots, cuff-less full-length pants, a flame-resistant and long-sleeve jacket, leather gloves, a welding helmet, safety glasses and a bandanna or skull cap to protect the top of your head from sparks and spatter.

Before tackling any welding project, make sure you have the proper safety apparel and that any potential fire hazards are removed from the welding area. Basic welding safety apparel includes leather shoes or boots, cuff-less full-length pants, a flame-resistant and long-sleeve jacket, leather gloves, a welding helmet, safety glasses and a bandanna or skull cap to protect the top of your head from sparks and spatter.

Metal preparation

As mentioned earlier, flux-cored welding is more tolerant of surface contamination than MIG welding. However, it’s always a good idea to clean the surface of the base metals as thoroughly as possible to ensure that a rusty or scaly surface does not contaminate the final weld. A metal brush or grinder work well for cleaning the base metals. Also, be sure to clean the portion of the base metal where the ground clamp will be attached. Poor contact with the ground clamp will create resistance in the welding circuit and could result in poor weld quality.

For material over 1/4 inch, it’s usually a good idea to bevel the edges of the base materials to ensure complete fusion of the two parts. This is especially true for butt joints.

Equipment preparation

Check your cables. Before striking an arc, check your welding equipment to make sure all of the cable connections are tight and free of fraying or other damage.

Check your cables. Before striking an arc, check your welding equipment to make sure all of the cable connections are tight and free of fraying or other damage.

Select electrode polarity. Flux-cored welding requires DC electrode negative, or straight polarity. The polarity connections are usually found on the inside of the machine near the drive rolls.

Use the correct drive rolls. Because flux-cored wire is softer than solid wire, knurled drive rolls provide a good “bite” on the wire without compressing and deforming it — which could happen if standard drive rolls are used.

Check wire tension. Too much or too little tension on either the drive rolls or the wire spool hub can lead to poor wire feeding performance. Adjust according to your owner’s manual.

Inspect consumables. Remove excess spatter from contact tips, replace worn contact tips and liners and discard the wire if it appears rusty.

Wire selection

For general purpose mild steel applications, a flux-cored wire with the designation E71T-11 can be used in any position, is available in a wide range of sizes and provides excellent welding characteristics for both thin and thicker material. Hobart® Filler Metals offers such a wire under the name Fabshield® 21B (E71T-11).

As for wire diameter, .030-inch diameter is a good all-around choice for welding a wide range of metal thicknesses. For welding thicker material at higher total heat levels, use .035-inch wire (or .045-inch wire if it’s within your welder’s output range).

Voltage and amperage

How much voltage and amperage a weld requires depends on metal thickness, joint configuration, welding position and wire diameter. Reference charts are available on your power source to help set the correct voltage and wire feed speed based on the wire diameter and material thickness. This flux-cored welding calculator is also a great tool to utilize. These tools should be considered rough guides from which you can fine-tune your final parameters based on a few test welds.

Wire stick-out

Stickout is the length of unmelted electrode extending from the tip of the contact tube, and it does not include arc length. Generally, flux-cored welding requires a stickout of around 3/4 inch, which is about twice the recommended stickout for MIG welding.

Stickout is the length of unmelted electrode extending from the tip of the contact tube, and it does not include arc length. Generally, flux-cored welding requires a stickout of around 3/4 inch, which is about twice the recommended stickout for MIG welding.

Push or drag?

With flux-cored welding, you should always use a drag (pull) technique, in which the tip of the welding gun is being pointed back at the weld pool and dragged away from the completed weld. An easy rule of thumb for remembering whether to use a push or drag (backhand) technique is: “If there’s slag, you drag.”

Watch video to learn about travel angle, work angle, flat position, horizontal position, vertical position and overhead position.

Overhead position

An overhead weld is the most difficult weld to make, and it should be avoided if possible. If you cannot avoid welding in the overhead position, try using the smallest wire possible, lowering your welding parameters by 15 to 20 percent, keeping your weaving to a minimum and maintaining a fast travel speed. Even following these tips, it still may be difficult to achieve a sound overhead weld.

Practice, practice, practice!

Creating a successful flux-cored weld (or any arc weld for that matter) requires more than just memorizing the correct parameters and gun travel guidelines. Only through practice and learning to read the weld pool will you be able to consistently achieve sound flux-cored welds. With practice, you’ll begin to learn to troubleshoot and self-correct any shortcomings in your welds.

So, don’t get frustrated if your welds don’t look perfect on your first try. Just keep practicing and before you know it, you’ll be scouring your garage for new things to repair or fabricate!

Visit MillerWelds.com for more insights!